I have a product made of four parts: P1...P4. Of each part I know mass, manufacturing process, material, EoL scenario. I'm using the IDEMAT ecoDB.

My intention is to model the LCA in order to have the impact of each phase (PreProd, Manufacturing, Use, EoL) of each part.

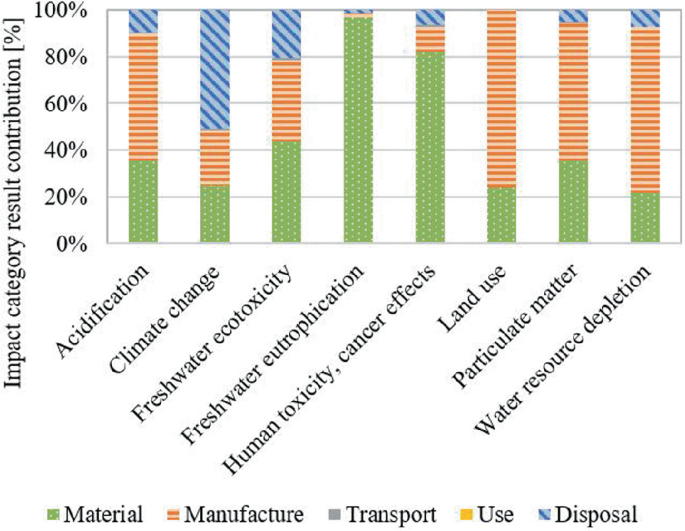

How do I model the LCA in order to have an output similar to this image?

I looked at the YouTube tutorials and the ones that were closer to my use case were the PET bottle and the Scooters.

From what I gathered, I should follow this process (I will take P1 as example):

- PRE-PRODUCTION

I create a P1_PREPROD flow of type "Product", with "Amount" unit. - I create a P1_PREPROD process for it, that takes as input:

- [mass] amount of [idemat_material] from [idemat_provider]

- MANUFACTURING

I create a P1_MANUF flow of type "Product" with "Amount" unit. - I create a P1_MANUF process for it, that takes as input:

- 1 unit of P1_PREPROD flow

- [mass] amount of [idemat_injection_molding] from [idemat_provider]

- USE

... - TRANSPORT

... - EOL

...

Recursively, unit I end up with four product flows: P1_PREPROD, P1_MANUF, P1_TRANSPORT, P1_USE, P1_EOL. Then:

- I create a P1_LIFECYCLE "Product" flow, "Amount" unit.

- I create a process for it, that takes as input:

- P1_PREPROD

- P1_MANUF

- P1_TRANSPORT

- P1_USE

- P1_EOL - Add this new created process to a product system

- Run the analysis

Is that correct or am I missing something here? This all looks VERY complex to me, but it's what I understood from the videos...