The procedure of end-of-life (EoL) modelling in openLCA varies among databases. In general, there are two different approaches.

1) Opposite Direction Approach (ODA)

2) Material Flow Logic Approach (MFLA)

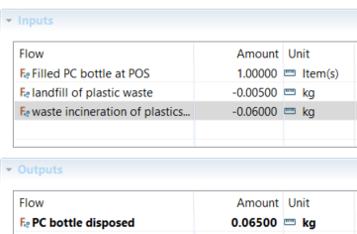

Opposite Direction Approach (ODA)

This is actually quite simple. You do not even need a waste flow. The ODA (double-negative) approach can be implemented under use of a product flow as a quantitative reference of the waste treatment process. Just think a moment what a 'quantitative reference' in openLCA actually is. The quantitative reference is the main output/product of a process. Hence, a process transforms all inputs into one or more outputs (the latter in the case of co-products) whilst emitting emissions (e.g. green house gases, toxic substances, etc.). However, when dealing with end-of-life or treatment you do not really have a main output besides emissions or in other words elementary flows ("material or energy entering the system [...] that has been drawn from the environment without previous human transformation, or material or energy leaving the system [...] that is released into the environment without subsequent human transformation" Source: ISO 14040:2006). A waste treatment does not produce a product flow but only emissions. Therefore, you want to put the quantitative reference on the input side. Since (for a product flow) this is not possible in openLCA, you are doing this mathematically by introducing a negative sign in front of the quantitative reference. Analogously, the quantitative reference of the waste treatment process has to be added to the input side of the waste generating process with a negative sign.

Waste generating process: The waste (non-waste flow) is a negative input

Waste treatment process: The waste (non-waste flow) is a negative output

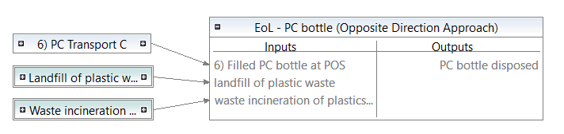

A screenshot of a waste generating process:

A screenshot of the model graph:

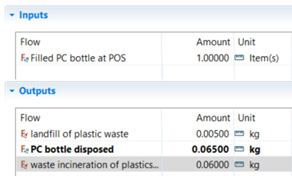

Material Fow Logic Approach (MFLA)

Waste flows were introduced with openLCA 1.7 and allow following the physical direction of material flows. They render the ODA approach redundant (at least if you are working with a database that follows the MFLA approach e.g. GaBi (at the time of writing)) Waste flows can be assigned as a quantitative reference albeit being an input of a waste treatment process. Analogously, waste flows can remain on the output side of the waste generating process.

Waste generation process: The waste (waste flow) is a positive output

Waste treatment process: The waste (waste flow) is a positive input

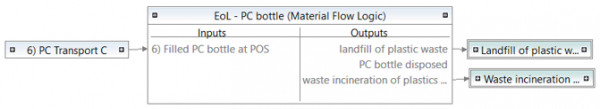

A screenshot of a waste generating process:

A screenshot of the model graph:

Concluding remark:

There is no definite answer on which waste modelling approach in openLCA works best. In fact, if implemented correctly, both approaches will lead to the exact same result. It's probably best if users follow the approach that is used in the background database with which they are working (e.g. ODA in ecoinvent and MFLA in GaBi). To find out which approach is used, open waste treatment processes and check whether waste flows (MFLA) are utilised or not (ODA). We will also soon publish an improved version of the PC/PET bottle tutorial on

https://openLCA.org including end-of-life modelling.

I hope this helps.