Dear community,

I have recently played around with Analysis Groups to investigate the hotspots of a separation process. It is modelled as a waste treatment process.

I use openLCA 2.5.0 and ecoinvent cut-off UPR 3.11

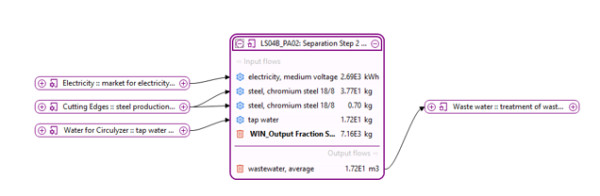

As an input, I use Elecricity, water and steel. Here the steel represents the cutting edges, which are regularly changed. Because I have two cutting edge components, i originally have two inputs of the same material:

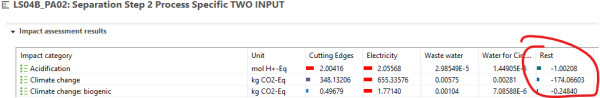

You can also see the assigneg analysis groups. For this product system i get corrupted results for the analysis groups with a large rest.

However, if i adapt the process and sum up the steel inputs into one flow the results are caculated correctly.

My main motivation to post this is that I am seeking for a deeper understanding of the function "analysis groups". Can you explain to me why the results come out this way? Is there some documentation on the algorithm behind it? I personally love the functionality, but I dont really feel capable of correctly implementing it in a consistent manner.

Thanks,

Paul