Hi everyone,

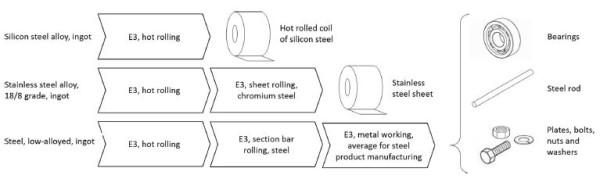

I'm trying to model the production of various metal parts for a project, but I'm having trouble understanding the metal processing/transformation process integrated into the ecoinvent database. From what I can gather, for example, "steel, low-alloyed" needs to be processed by "hot rolling, steel", "section bar rolling, steel" and "metal working, average for steel product manufacturing" to be transformed into e.g. a bearing.

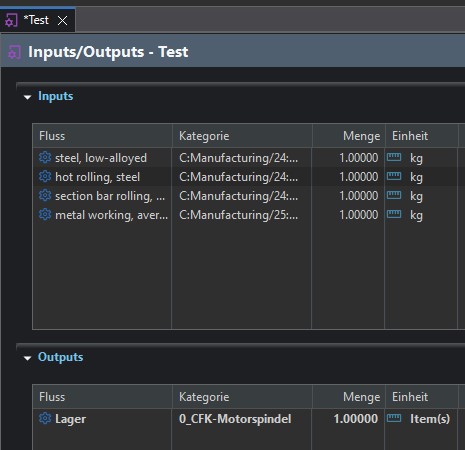

So I assume that if I want to produce 1 kg of bearings, I would need 1 kg of 'low-alloyed steel' (loss will be neglected) and 1 kg of each transformation processes. Their documentation states that the material being processed is not included. I would model them like this (please correct me if I am wrong):

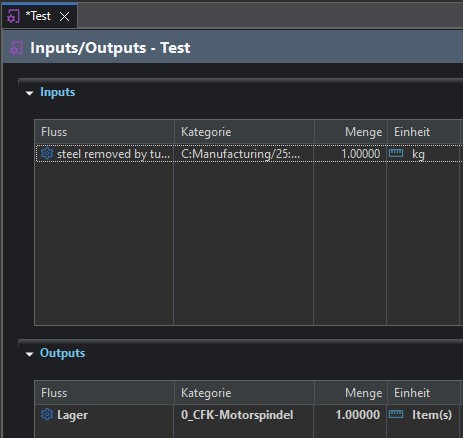

The problem I have, though, is to understand such processes as "steel turning, average, computer numerical controlled". Since it refers to the amount of steel being removed, and input materials are already included (documentation), I assume that if I want to produce 1kg of a product, which needs to be processed this way, I'd only need 1kg of "steel turning, average, computer numerical controlled" .....?

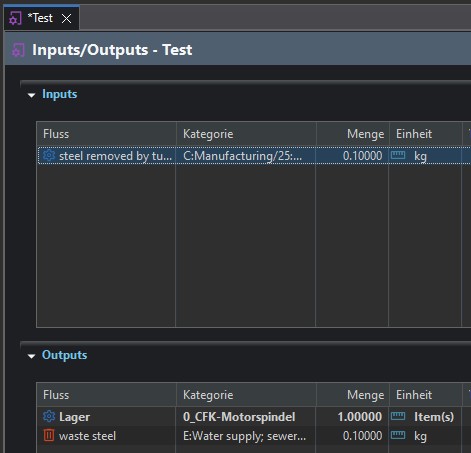

Or do i need to know how much steel is removed (because the process refers to it) and model it this way?

I'm really sorry if its confusing.. Thank you in advance for your attention and help!!