I'm modelling lithium production through a battery recycling process with spent batteries in the input and Ni, Co, and Li products in the output. I'm using the Ecoinvent 3.10 cut-off database.

I just noticed that there is the waste flow "used Li-ion battery" in the database, but I'm not sure about it's meaning in the input. As I understand, by choosing "avoided waste" for it in the input (as it is a waste flow coming into a recycling process), it should take into account (at least some of) the previous life cycle impacts of the battery as well. It's not a cut-off approach anymore, right?

Calculating the results this way seems to decrease the net impacts slightly.

On the other hand, if I use a "basket-of-products" approach for the Ni, Co, and Li products, the results are hugely different (and negative) compared to using substitution for the by-products (Ni & Co).

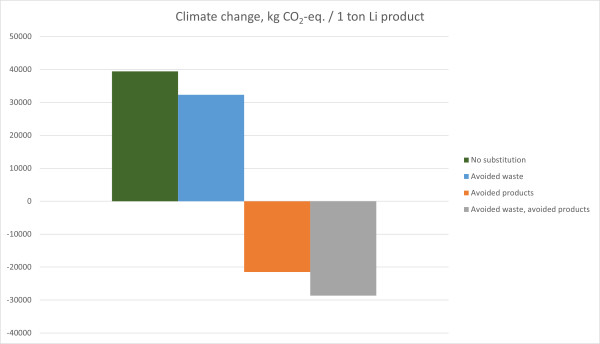

Below is a figure illustrating the Climate change impact of 1) using no substitution at all (spent batteries are used in the input without the "avoided waste", and a full basket-of-products with no "avoided products" in the output, 2) "avoided waste" only for the spent batteries in the input, 3) "avoided products" only for the Ni and Co by-products, and 4) "avoided waste" for the spent batteries in the input and "avoided products" for the Ni and Co by-products in the output. No allocation was used in any of the cases.

So, my question is, if I want to model the Li production in a simple scenario (comparing it to other sources of Li, for example), which approach should I use? My own thinking would go towards using the "avoided waste" for spent batteries, and allocating the basket-of-products either economically or physically to scale the results for Li only. What would you say?