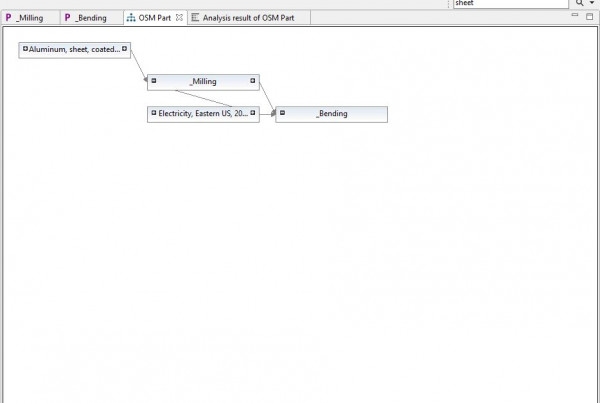

Hi all, Lets say my product system (OSM Part) has two processes involved.

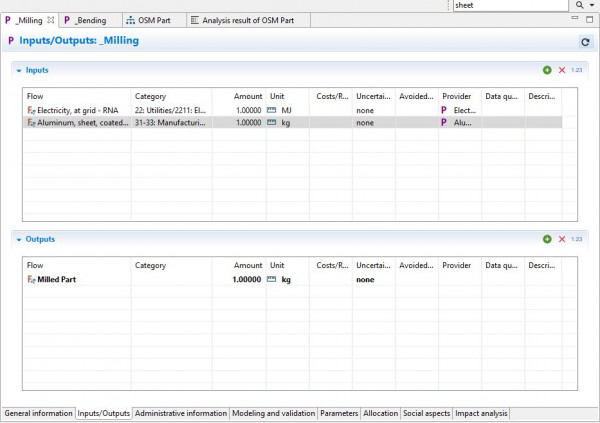

1. Milling (input : Aluminum sheet and electricity; output: Milled part)

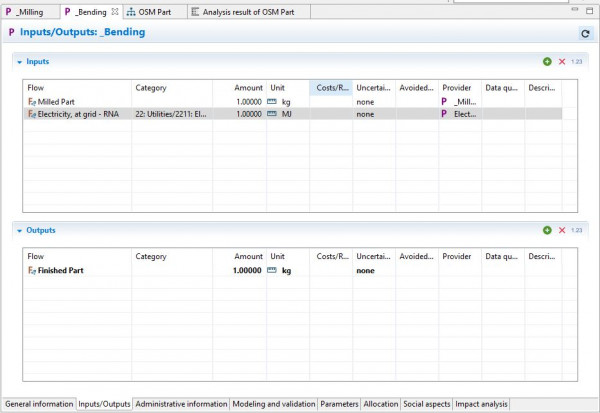

2. Bending (input: Milled part and electricity; output: Finished part)

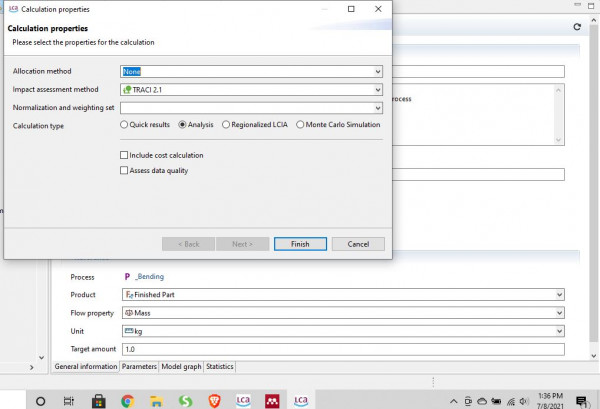

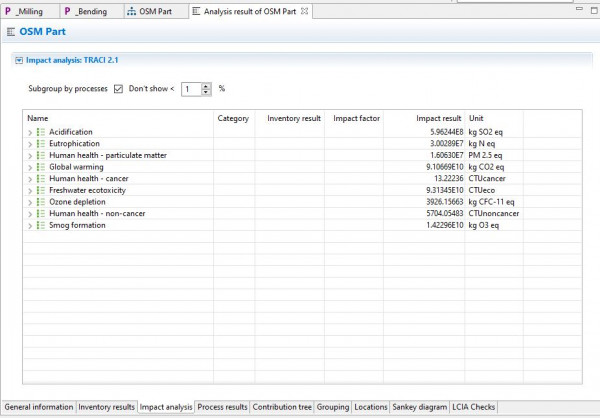

While creating the product system, I ticked the Auto-link processes option and selected unit processes since my boundary is cradle to gate. I kept the values as 1 unit for this trail calculation, but the impact result I got doesn't make sense at all (i mean the impact results are huge). I am attaching some screen shots of the processes and results. It would be really helpful if someone can point out what I might have done wrong.

I am using USLCI database and TRACI 2.1